Automated Guided Vehicle (AGV) Manufacturers: A Comprehensive Overview (Updated October 2, 2026)

This overview details leading AGV brands like Dematic, Daifuku, Toyota, and KUKA, alongside emerging innovators, aiding selection for logistics and manufacturing needs.

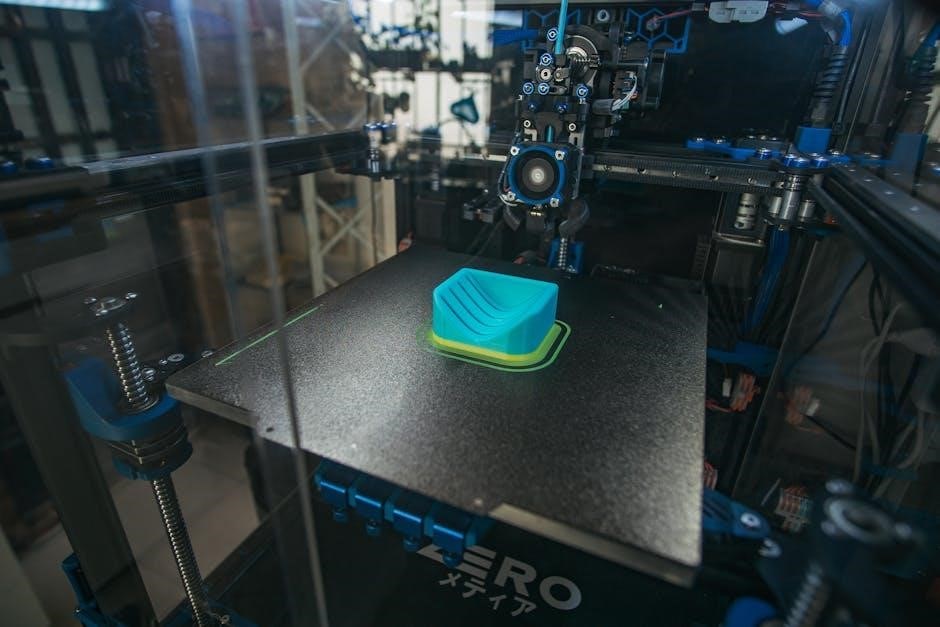

Automated Guided Vehicles (AGVs) represent a pivotal technology in modern industrial automation and intelligent manufacturing, transforming material handling processes across diverse sectors. These driverless vehicles navigate predefined paths, enhancing efficiency, safety, and productivity within facilities. Initially relying on wire guidance, AGVs have evolved significantly, now incorporating laser guidance, vision guidance, and sophisticated Simultaneous Localization and Mapping (SLAM) technologies.

The increasing demand for AGVs stems from the need to optimize warehouse operations, streamline production lines, and reduce labor costs. Manufacturers and suppliers are actively integrating AGV solutions, particularly within the automotive industry, to improve quality control and overall operational performance. This comprehensive overview explores the leading AGV manufacturers and their respective contributions to this rapidly evolving field.

The Growing Demand for AGVs in Manufacturing and Logistics

The surge in AGV adoption is directly linked to the escalating pressures within manufacturing and logistics to enhance efficiency and responsiveness. Accelerated industrial automation and the pursuit of intelligent manufacturing are key drivers, as companies seek to optimize material flow and reduce operational expenses. Warehouses, in particular, benefit from AGVs’ ability to automate repetitive tasks, improving throughput and minimizing errors.

Automotive manufacturers and their suppliers are at the forefront of AGV implementation, leveraging these systems for precise material delivery and quality control. This demand fuels innovation among AGV manufacturers, leading to more sophisticated navigation, safety features, and integration capabilities, ultimately reshaping the landscape of industrial logistics.

Leading AGV Manufacturers – Global Landscape

Key players include Dematic, Daifuku, Toyota Industries, and KUKA, dominating the global AGV market with diverse solutions for various industrial applications.

Dematic (KION Group)

Dematic, a KION Group company, stands as a prominent global supplier of automated material handling systems and services, including a robust portfolio of AGVs. They offer solutions spanning various industries, with a strong focus on optimizing warehouse and distribution operations. Dematic’s AGVs are known for their scalability and integration capabilities, seamlessly connecting with existing infrastructure.

Their expertise extends to quality control applications, supporting automotive manufacturers and suppliers in streamlining production processes. Dematic consistently invests in research and development, ensuring their AGV technology remains at the forefront of innovation, delivering reliable and efficient material flow solutions for complex logistical challenges.

Dematic’s AGV Product Portfolio

Dematic’s AGV offerings encompass a diverse range of vehicles designed for varied payload capacities and operational requirements. Their portfolio includes unit load AGVs for transporting pallet-sized loads, and smaller, more agile vehicles suited for handling individual totes or containers. They provide both traditional wire-guided AGVs and more modern, flexible solutions leveraging laser guidance and natural navigation technologies.

Dematic also delivers customized AGV solutions tailored to specific customer needs, integrating seamlessly with their broader automation systems. This comprehensive approach ensures optimal performance and efficiency within the entire material handling process, supporting diverse applications across manufacturing and distribution centers.

Dematic’s Market Position and Strengths

Dematic, as part of the KION Group, holds a strong global market position in the AGV industry, bolstered by decades of experience in material handling solutions. Their key strength lies in providing complete, integrated systems, rather than simply supplying vehicles. This includes software, fleet management, and comprehensive support services.

Dematic’s extensive industry knowledge allows them to effectively address complex automation challenges, particularly in quality control applications. They excel in partnering with automotive manufacturers and suppliers, delivering tailored AGV solutions that enhance production efficiency and streamline logistics operations. Their reliability and scalability are highly valued.

Daifuku (Japan)

Daifuku, a prominent Japanese corporation, specializes in comprehensive material handling systems, with AGVs forming a crucial component of their offerings. They’ve established a strong reputation for delivering robust and reliable solutions tailored to diverse industrial environments. Daifuku distinguishes itself through continuous technological advancements, consistently integrating cutting-edge features into their AGV designs.

Their focus extends beyond basic vehicle functionality, encompassing sophisticated software and control systems for optimized fleet management. Daifuku’s commitment to innovation ensures their AGVs meet the evolving demands of modern manufacturing and logistics, providing efficient and adaptable automation solutions for their clients worldwide.

Daifuku’s Specialization in Material Handling AGVs

Daifuku’s core competency lies in developing AGVs specifically engineered for intricate material handling tasks. They excel in providing solutions for transporting a wide array of materials, from raw components to finished goods, within manufacturing and warehousing facilities. Their AGVs are designed to navigate complex layouts and seamlessly integrate into existing production lines.

This specialization allows Daifuku to offer customized AGV systems optimized for specific material characteristics and handling requirements; They focus on enhancing operational efficiency, reducing labor costs, and improving overall supply chain performance through their specialized material handling AGV solutions.

Daifuku’s Technological Advancements

Daifuku consistently invests in cutting-edge technologies to enhance its AGV capabilities. Modern AGVs from Daifuku increasingly incorporate SLAM (Simultaneous Localization and Mapping) for real-time mapping, path planning, and autonomous navigation without relying on fixed infrastructure. This allows for greater flexibility and adaptability within dynamic environments.

Furthermore, Daifuku focuses on developing sophisticated fleet management systems that optimize AGV traffic flow, minimize congestion, and maximize throughput. These advancements contribute to improved operational efficiency, reduced downtime, and enhanced overall productivity for their clients in various industries.

Toyota Industries (Japan)

Toyota Industries is renowned for its commitment to reliability and efficiency in AGV solutions. They’ve established a strong presence, particularly within the automotive industry, providing tailored AGV systems for complex manufacturing processes. Automotive manufacturers and suppliers frequently partner with Toyota to implement these solutions, streamlining production lines and material flow.

Toyota’s AGVs are designed for robust performance and minimal maintenance, aligning with the Toyota Production System’s principles. This focus ensures consistent operation and reduces total cost of ownership for customers seeking dependable automation solutions.

Toyota’s Focus on Reliability and Efficiency

Toyota Industries prioritizes reliability and efficiency in its AGV design and manufacturing processes. This dedication stems from the core principles of the Toyota Production System, emphasizing continuous improvement and minimizing waste. Their AGVs are engineered for robust performance, capable of withstanding demanding industrial environments and maintaining consistent operation over extended periods.

This focus translates to reduced downtime, lower maintenance costs, and increased overall productivity for customers. Toyota’s commitment ensures their AGV solutions deliver long-term value and contribute to streamlined, efficient workflows.

Toyota’s AGV Solutions for Automotive Industry

Toyota Industries provides specialized AGV solutions tailored for the automotive industry’s unique demands. These solutions support various applications, including parts delivery to assembly lines, finished vehicle handling, and pallet transportation within manufacturing facilities. Automotive manufacturers and suppliers partner with Toyota to implement AGVs, enhancing production efficiency and reducing material handling costs.

Toyota’s AGVs integrate seamlessly into complex automotive workflows, improving logistics and enabling just-in-time delivery of components. This results in optimized production processes and enhanced responsiveness to market changes.

KUKA (Germany, Midea Group)

KUKA, a German company now part of the Midea Group, is a prominent player in AGV technology, renowned for its integration capabilities with robotic systems. This synergy allows for highly automated and flexible material handling solutions across diverse industries. KUKA’s AGVs aren’t simply transporters; they are intelligent components within a larger automation ecosystem.

The company’s focus extends beyond basic movement, offering solutions that optimize workflows and enhance overall production efficiency. KUKA’s AGVs are deployed in applications ranging from automotive manufacturing to logistics and beyond, demonstrating their versatility.

KUKA’s AGV Integration with Robotics

KUKA distinguishes itself through seamless AGV integration with its extensive robotics portfolio. This combination creates powerful, automated workflows where AGVs deliver materials directly to robotic workstations, eliminating manual intervention and boosting productivity. The synergy allows for complex tasks, such as machine tending and assembly, to be performed with greater precision and speed.

KUKA’s approach isn’t merely about connecting robots and AGVs; it’s about creating a cohesive, intelligent system. This integration streamlines processes, reduces errors, and optimizes material flow, resulting in significant operational improvements for manufacturers.

KUKA’s AGV Applications in Diverse Industries

KUKA’s AGV solutions demonstrate versatility across numerous sectors, extending beyond traditional manufacturing. Automotive manufacturers leverage them for just-in-time delivery of components, enhancing assembly line efficiency. In the electronics industry, AGVs handle sensitive materials with precision, minimizing damage and ensuring product quality.

Furthermore, KUKA AGVs find applications in the food and beverage industry, transporting ingredients and finished goods in hygienic environments. Even in healthcare, they assist with material transport within hospitals and laboratories. This broad applicability underscores KUKA’s ability to tailor solutions to specific industry challenges.

Emerging AGV Manufacturers and Innovators

Innovative companies like Otto Motors, MiR, and Locus Robotics are reshaping the AGV landscape with advanced AMRs and collaborative robotic solutions.

Otto Motors

Otto Motors distinguishes itself through a dedicated focus on Autonomous Mobile Robots (AMRs), leveraging sophisticated Simultaneous Localization and Mapping (SLAM) technology for dynamic navigation. This allows their robots to operate flexibly in changing environments without relying on fixed infrastructure like wires or magnets.

Beyond the robots themselves, Otto Motors provides comprehensive software and fleet management solutions. These tools enable businesses to efficiently deploy, monitor, and optimize their AMR fleets, maximizing productivity and minimizing downtime. Their systems are designed for ease of integration and scalability, catering to diverse operational requirements within modern facilities. The company’s approach emphasizes intelligent automation and streamlined workflows.

Otto Motors’ Focus on Autonomous Mobile Robots (AMRs) & SLAM Technology

Otto Motors champions AMRs, diverging from traditional AGVs by employing advanced SLAM technology. This enables real-time mapping, path planning, and localization, allowing robots to navigate dynamically and adapt to changing environments. Unlike AGVs needing fixed pathways, Otto’s AMRs offer unparalleled flexibility.

SLAM empowers these robots to build and update maps concurrently, ensuring accurate positioning even without pre-defined infrastructure. This capability is crucial for complex, evolving industrial settings. Otto Motors’ commitment to SLAM-based AMRs signifies a shift towards more intelligent and adaptable material handling solutions, optimizing workflows and boosting operational efficiency.

Otto Motors’ Software and Fleet Management Solutions

Otto Motors provides comprehensive software solutions designed to manage and optimize AMR fleets effectively. Their platform offers real-time visibility into robot performance, location, and task completion, streamlining operations and maximizing throughput. Fleet Manager allows for centralized control, task assignment, and monitoring of multiple AMRs simultaneously.

Beyond basic fleet management, Otto’s software integrates with existing warehouse systems, facilitating seamless data exchange and workflow automation. This connectivity enhances overall efficiency and reduces manual intervention. The intuitive interface and robust analytics empower users to identify bottlenecks, optimize routes, and proactively address potential issues, ensuring a consistently productive AMR deployment.

MiR (Mobile Industrial Robots)

MiR specializes in collaborative mobile robots (cobots) designed for internal transport and logistics. Their AMRs are known for their user-friendly interface and ease of programming, enabling quick deployment and adaptation to changing environments. MiR robots navigate dynamically, avoiding obstacles and working safely alongside people without the need for safety fencing.

The company offers a range of models catering to diverse payload requirements, from lightweight applications to heavier-duty tasks. MiR’s focus on flexibility and scalability makes them a popular choice for businesses seeking to automate material handling processes and improve operational efficiency. They provide solutions for various industries.

MiR’s Collaborative Mobile Robots (Cobots)

MiR’s core offering revolves around collaborative mobile robots, or cobots, distinguished by their ability to safely operate alongside human workers. These AMRs are equipped with advanced sensors and safety features, ensuring collision avoidance and responsive navigation within dynamic environments. Unlike traditional AGVs, cobots don’t require fixed pathways or safety infrastructure like fences.

This collaborative nature allows for flexible automation of internal transport tasks, improving workflow efficiency without disrupting existing operations. MiR cobots handle repetitive and physically demanding jobs, freeing up personnel for more value-added activities. Their intuitive interfaces simplify programming and integration.

MiR’s Applications in Light Payload Transportation

MiR excels in automating the transport of light payloads, typically ranging up to several hundred kilograms. Their robots are widely deployed in scenarios involving internal logistics within factories, warehouses, and hospitals. Common applications include delivering materials to assembly lines, transporting components between workstations, and handling finished goods.

These AMRs efficiently move items like parts, tools, documents, and laundry, optimizing material flow and reducing manual handling. MiR’s solutions are particularly valuable in environments requiring frequent changes in layout or delivery routes, offering a flexible alternative to fixed conveyor systems. They enhance productivity and reduce operational costs.

Locus Robotics

Locus Robotics revolutionizes warehouse automation with its collaborative robots, designed to work alongside human workers; Their system utilizes autonomous mobile robots (AMRs) that navigate warehouses to assist pickers, significantly boosting order fulfillment speed and accuracy. Locus focuses on optimizing the “goods-to-person” workflow, bringing shelves directly to employees.

This approach reduces travel time for workers and minimizes errors, leading to increased productivity and improved labor utilization. Locus’s multi-robot collaboration allows for scalable deployments, adapting to fluctuating demand. Their solutions are particularly effective in e-commerce fulfillment and retail distribution centers.

Locus Robotics’ Warehouse Automation Solutions

Locus Robotics delivers comprehensive warehouse automation solutions centered around its AMR-based system. These solutions dramatically improve order fulfillment efficiency by integrating seamlessly with existing warehouse infrastructure and workflows. Their robots collaborate with warehouse staff, reducing walking distances and enhancing picking accuracy.

Locus offers scalable deployments, adapting to varying warehouse sizes and operational demands. The system’s intelligent software optimizes robot routes and task assignments, maximizing throughput. Key benefits include increased order fulfillment rates, reduced labor costs, and improved worker ergonomics, ultimately transforming warehouse operations for greater profitability.

Locus Robotics’ Multi-Robot Collaboration

Locus Robotics excels in multi-robot collaboration, deploying fleets of AMRs that work harmoniously alongside warehouse personnel. This collaborative approach distinguishes Locus from traditional automation, fostering a human-robot synergy that boosts overall productivity. Their system dynamically assigns tasks to robots, optimizing workflow and minimizing congestion within the warehouse environment.

The robots communicate and coordinate movements, ensuring efficient navigation and preventing collisions. This sophisticated collaboration enables warehouses to handle increased order volumes and adapt to fluctuating demands. Locus’s solution provides a flexible and scalable automation strategy, enhancing operational resilience and responsiveness.

AGV Technology and Key Features

Modern AGVs utilize technologies like wire guidance, laser guidance, vision guidance, and SLAM for navigation, alongside robust safety systems and adherence to industry standards.

Navigation Technologies: Wire Guidance, Laser Guidance, and Vision Guidance

AGVs employ diverse navigation methods to traverse facilities autonomously. Traditional wire guidance uses circuits embedded in the floor, offering a reliable, yet inflexible, path. Laser guidance utilizes rotating lasers to map surroundings and follow defined routes, providing greater flexibility than wire guidance.

More recently, vision guidance has emerged, leveraging cameras and image processing to navigate based on visual landmarks – offering significant adaptability and eliminating the need for physical infrastructure. Each technology presents trade-offs regarding cost, complexity, and suitability for different environments; The selection depends on the specific application, facility layout, and required level of flexibility within the automated system.

SLAM (Simultaneous Localization and Mapping) in Modern AGVs

Modern AGVs increasingly integrate SLAM (Simultaneous Localization and Mapping) technology, representing a significant advancement in autonomous navigation. Unlike traditional methods, SLAM enables AGVs to create and update maps of their environment in real-time, concurrently localizing themselves within that map.

This capability allows for dynamic path planning, obstacle avoidance, and operation in unstructured environments without relying on pre-defined infrastructure. Companies like Otto Motors are at the forefront of implementing SLAM, enhancing AGV flexibility and adaptability. SLAM empowers AGVs to respond to changes in the facility layout, improving overall efficiency and reducing downtime.

AGV Safety Systems and Standards

Safety is paramount in AGV operation, driving the implementation of robust safety systems and adherence to stringent standards; These systems commonly include emergency stop buttons, safety scanners, and warning lights/sounds to prevent collisions and ensure personnel safety.

AGV manufacturers prioritize compliance with relevant industry standards, such as ANSI/ITSDF B56.5, which outlines safety requirements for AGVs. Advanced features like speed monitoring and zone control further enhance safety. Integrating these systems minimizes risks in dynamic environments, fostering a secure collaboration between AGVs and human workers within manufacturing and logistics facilities.

Choosing the Right AGV Manufacturer

Selecting the ideal vendor requires a fit-by-scenario approach, considering payload, navigation, integration, quality control, and comprehensive supplier support for optimal results.

Fit-by-Scenario: Matching Vendor to Specific Needs

Successfully integrating AGVs demands a precise vendor selection aligned with unique operational requirements. Automotive manufacturers often prioritize reliability, making Toyota a strong contender. For complex, integrated robotic solutions, KUKA’s expertise shines.

Warehouses seeking flexible, collaborative robots will find MiR ideal, while Locus Robotics excels in multi-robot warehouse automation. Dematic provides comprehensive material handling solutions, and Daifuku specializes in intricate systems.

Otto Motors, with its focus on AMRs and SLAM technology, suits dynamic environments. A thorough needs assessment—considering payload, navigation type, and existing infrastructure—is crucial for a successful partnership.

Key Considerations: Payload, Navigation, and Integration

Selecting an AGV necessitates careful evaluation of payload capacity, ensuring it meets material handling demands. Navigation technology—wire guidance, laser, or vision—impacts flexibility and cost. Modern AGVs increasingly utilize SLAM for dynamic mapping and autonomous movement, as seen with Otto Motors.

Seamless integration with existing systems (WMS, ERP) is paramount. Consider the vendor’s integration capabilities and support services. Safety systems and adherence to industry standards are non-negotiable.

Evaluate the AGV’s adaptability to your facility’s layout and potential future expansion. A well-considered approach to these factors maximizes ROI and operational efficiency.

Evaluating AGV Suppliers: Quality Control and Support

Rigorous quality control is crucial when selecting an AGV supplier; assess their manufacturing processes and certifications. A reliable supplier provides comprehensive support, including installation, training, and ongoing maintenance. Prompt access to spare parts minimizes downtime, vital for continuous operations.

Investigate the supplier’s track record and customer testimonials. Consider their responsiveness to inquiries and problem-solving capabilities.

Evaluate the availability of remote diagnostics and preventative maintenance programs. A strong partnership with a supportive supplier ensures long-term AGV performance and maximizes investment value.